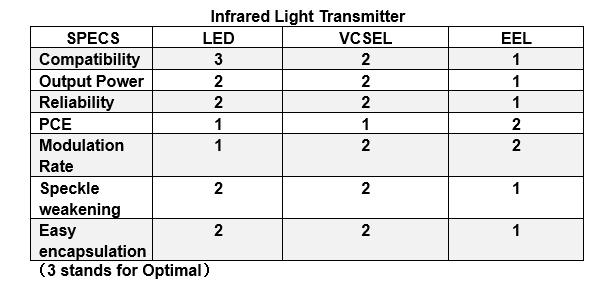

Comparing with LED and EEL, VCSELs have several significant advantages.

Compatibility: VCSEL’s semiconductor manufacturing and wafer integration is compatible with other probes and circuits.

Low power: the low power and high efficiency of VCSEL not only extends the battery service time, but also reduces the requirements for the cooling system of terminal products.

Reliability: VCSELs do not have traditional failure module which caused by structural characteristics, such as line defects. In addition as a result of the VCSEL each component service life is long enough, , unlike the LED or edge emitter line configuration mode, VCSEL can be arranged in the form of arrays, so a single or a few glowing point of damage will not make the whole system by catastrophic optical damage.

Extensibility: multiple VCSEL chips can be easily assembled into one-dimensional or two-dimensional arrays and the output power can be adjusted according to specific applications and requirements.

Testing: VCSEL can complete all test and aging on the complete wafer (without cutting), effectively reducing the manufacturing cost in production.